What measurement means for assembly tools?

Measurement means determining whether a requirement, such as the correct functionality or accuracy of a system or measuring instrument, is met. Normally, the result of a measurement is a measured value or a series of measured values. A measurement result always represents an estimation that is more or less precise and includes a measurement uncertainty. The objective of measurement is to make a clear statement about an unknown factor, which is a key component of quality assurance best practices in industrial assembly.

What “standard” means in an industrial context?

At Desoutter, we refer to a “standard” as a measurement instrument used in calibration processes.

A standard is the definition of a given quantity – i.e., it is a sort of reference, like the atomic clock kept by the German National Institute (PTB).

Physical dimensions such as torque, force, or temperature are standards. Most countries maintain their own national standards, which are compared at an international level. Standards used in the production process are referred to as working standards.

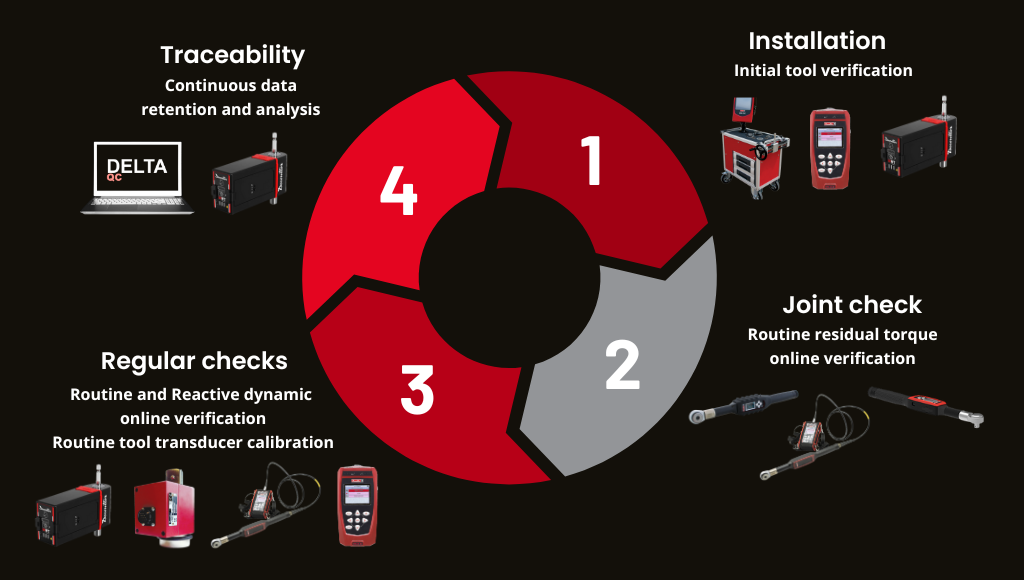

When does the verification step occur?

Verification is the process of checking an instrument against a reference unit to confirm that it complies with the specifications provided by its manufacturer. Calibration intervals for measuring instruments and production equipment depend on several factors, including:

- Quantity measured or produced

- Condition of measuring instruments and equipment

- Stability of past calibration results

- Quality assurance requirements

As a result, calibration intervals must be defined and monitored on a case-by-case basis, depending on the application and user requirements. This responsibility typically lies with the company’s quality manager.

For new equipment, calibration intervals are often set initially to a shorter period and then adjusted based on long-term stability. In most cases, annual calibration is sufficient, while safety-critical applications may require intervals of 6 months or even 3 months.

Why is certification a crucial step?

Certification is the confirmation of processes and routines related to norms and standards by an independent, accredited certification body. The certificate issued confirms compliance with applicable standards. Certificates are often issued with expiry dates and are verified independently to ensure compliance.

Want to know more about regulatory obligations? Check our latest dedicated article:

Quality assurance: Norms and standards you need to know

How is accuracy a crucial pillar of value?

Accuracy describes the ability of a measuring instrument or a machine to deliver values that are near to the true value. The machine capability indices Cm and Cmk are often mentioned in connection with accuracy. Discover more in our dedicated article: Machine capability index: Reference for accuracy assessment.

These indices were established in the automotive industry as a method of assessing the quality and suitability of power tools.

How does measurement uncertainty drive instrument choice?

Measurement uncertainty quantifies the accuracy of a measuring instrument under operating conditions. It is not a fixed value and must but determined individually for each instrument. It is used to determine whether a measuring instrument is suitable for the required quality process. The optimal choice of a measuring instrument saves costs as excessive accuracy may be unnecessary and . A classification of your joints (Criticity of assembly operations in the Control Plan) can help you in this process.

Why is residual torque checking important?

Residual torque checking is the process of measuring the remaining torque on a joint after tightening. This step ensures that the joint maintains the correct torque level and helps identify any potential relaxation. It is a critical step for safety-sensitive applications: detecting joint relaxation early prevents failures and guarantees compliance with torque specifications. Residual torque checking can be carried out during a new assembly process to confirm proper tightening or to verify relaxation under torque or over torque conditions.

It can be measured after tightening with various tools, including:

If the residual torque does not meet the specified tolerance, several corrective actions are possible from tool calibration check and joint inspection to retightening and rechecking.