Download User manuals, CAD files and more.

Our solutions in video!

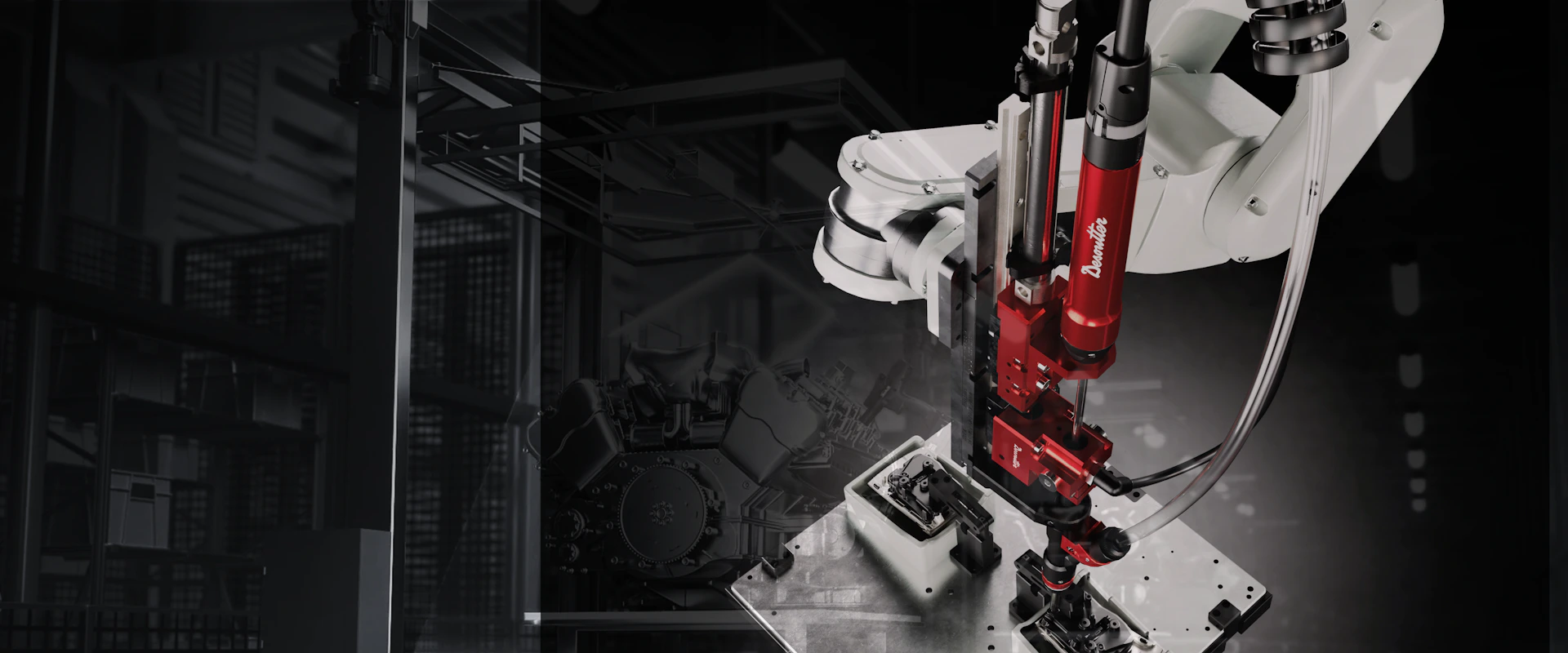

From Concept to Integration

Supporting your projects with design expertise and our wide range of assembly possibilities

Our centralised and local project teams are available to work on your projects. More than productivity - Desoutter enables integrators to build smarter, faster, and future-ready solutions for OEMs and Tier suppliers. We understand the challenges faced by integrators: accelerate system integration, ensure seamless interoperability and future-proof your client's installations.

Trusted by System integrators

Discover our tightening solutions in video

AXON. MULTI. Fixtured spindles.

Our best automation products in video

RAPID. eRAPID. ARG.

Desoutter, as a global leader in assembly and drilling solutions, provides system integrators with modules for customised smart assembly solutions. Our advanced portfolio of smart assembly tools, process control software, light automation, and services offer technologies that fit seamlessly into every client’s production environment. By partnering with Desoutter, integrators gain access to innovative and reliable industrial solutions that accelerate integration projects, reduce downtime, improve productivity, and deliver maximum value to their clients:

- Time & speed of commissioning, reliability in delivery time and pricing, reduced risk

- Modularity, scalability, flexibility

- Integration, the Desoutter ECOSYSTEM, dedicated service

Explore our automated vision systems in video

NAVIS. nexonar.

They trust us

Are you looking for expert support?

Any questions? Consult our FAQ

What advantages does Desoutter offer to system integrators when designing technical solutions?

Desoutter provides system integrators with a complete ecosystem of advanced assembly and process control solutions that are easy to configure and deploy. Our products are designed for flexibility, scalability, and connectivity, enabling system integrators to create customised solutions that meet their clients’ performance and quality requirements. Beyond our technology, we offer dedicated technical support, project guidance, and global service to help ensure the success of every integration.

How does Desoutter support system integrators throughout the project lifecycle?

From the initial design phase to on-site commissioning and after-sales service, Desoutter stands beside system integrators every step of the way. We provide access to training programmes, digital configuration tools, detailed documentation, and responsive technical support. Our experts work closely with system integrators to reduce project lead times, ensure seamless implementation, and deliver lasting performance for end users.

Are Desoutter solutions compatible with existing production systems and equipment?

Absolutely. Desoutter solutions are built on open communication standards and are designed for easy integration into a wide variety of industrial environments. Whether it’s connecting to MES, ERP, or traceability systems, our products ensure interoperability and scalability. This means system integrators can confidently modernise their clients’ production lines without disrupting existing operations.

How does Desoutter ensure data integrity and traceability within integrated systems?

Desoutter solutions are engineered to guarantee full data integrity and end-to-end traceability across connected systems. Our controllers and software platforms securely collect, store, and exchange process data in real time, supporting key industrial protocols such as OPC UA, MQTT, and REST API. This allows system integrators to build reliable, data-driven architectures that comply with Industry 4.0 and quality-assurance standards while providing complete visibility of every tightening or process step.

What type of information is sent by a vision system to a station or line orchestrator for tightening or drilling operations?

A vision system provides the precise coordinates of tightening or drilling points within the robot’s reference frame. At Desoutter, these coordinates are delivered in three dimensions, ensuring maximum accuracy and repeatability for automated processes. This is critical for integrators working on complex assembly lines in sectors such as automotive, aerospace, and high-tech infrastructures like data centers.

Can all main fieldbuses be used to communicate with a vision system?

Yes. The Desoutter vision system supports all major industrial fieldbuses, making it highly adaptable to most automation architectures. For integrators, this means seamless integration across multi-technology environments, without compromising performance or data security.

What should be considered when implementing the hardware for a vision system?

The camera position is a critical factor for system reliability. At Desoutter, we mount the camera module directly onto the tightening or drilling tool, delivering maximum flexibility and productivity gains. This approach reduces space constraints and simplifies deployment on complex assembly lines, where precision and efficiency are paramount.

What types of robotic systems can work with a screw feeder?

The RAPID screw feeder from the Desoutter range is designed for broad compatibility and can integrate seamlessly with various robotic platforms, such as industrial robots, collaborative robots (cobots), SCARA models, and even linear-motion systems like XY-axis devices.