When we speak about calibration work on tightening systems, there are two measured dimensions to especially take into account: torque and angle. These two dimensions may be considered either separately or in combination. In this article, discover their impacts on calibration and understand why they are central to any precision tightening strategy.

General Industries

Aerospace

Datacenters

Automotive

New energy vehicles

Precision tightening: Torque and angle, the essentials of industrial calibration

Torque, first parameter of an adequate calibration work

In connection with tightening systems, torque calibration is the most widely used approach to ensure the proper functioning of the equipment used and the quality of bolted joints. It is normal practice to use measuring instruments in production to verify the quality achieved by a tightening tool. As torque remains a fundamental variable in precision tightening, accurate calibration directly impacts the reliability and repeatability of assemblies.

Angle, a key dimension to get precise tightening

Angle calibration is important in connection with angle-controlled tightening procedures. In practice, these procedures are not yet used as frequently as torque-controlled tightening procedures, but they are very useful in certain applications and are becoming increasingly important. Using the angle measurement to control the tightening process means that one must also calibrate this dimension to ensure the measurements – and therefore the bolted joints - are correct. This also applies to quality control equipment measuring “installed torque” (e.g., torque/angle wrenches) where the angle is used as one essential parameter for evaluating results.

Angle measurement: The answer for bolted joints

As bolted joints become more complex, the topic of angle calibration becomes more important for companies. Especially in the case of safety-critical bolted joints (category A joints defined by VDI 2862), it is necessary to document a monitoring variable (e.g., angle) in addition to the control variable (e.g., torque). In such cases, angle is often the most practicable solution. Examples of safety-critical bolted joints can be found in safety belt or airbag installations in cars or on the rotor blades of wind turbines. If these bolted joints fail, there is a direct risk of injury or death.

Explore the use cases below to quickly understand the impact of torque and angle on bolted joints:

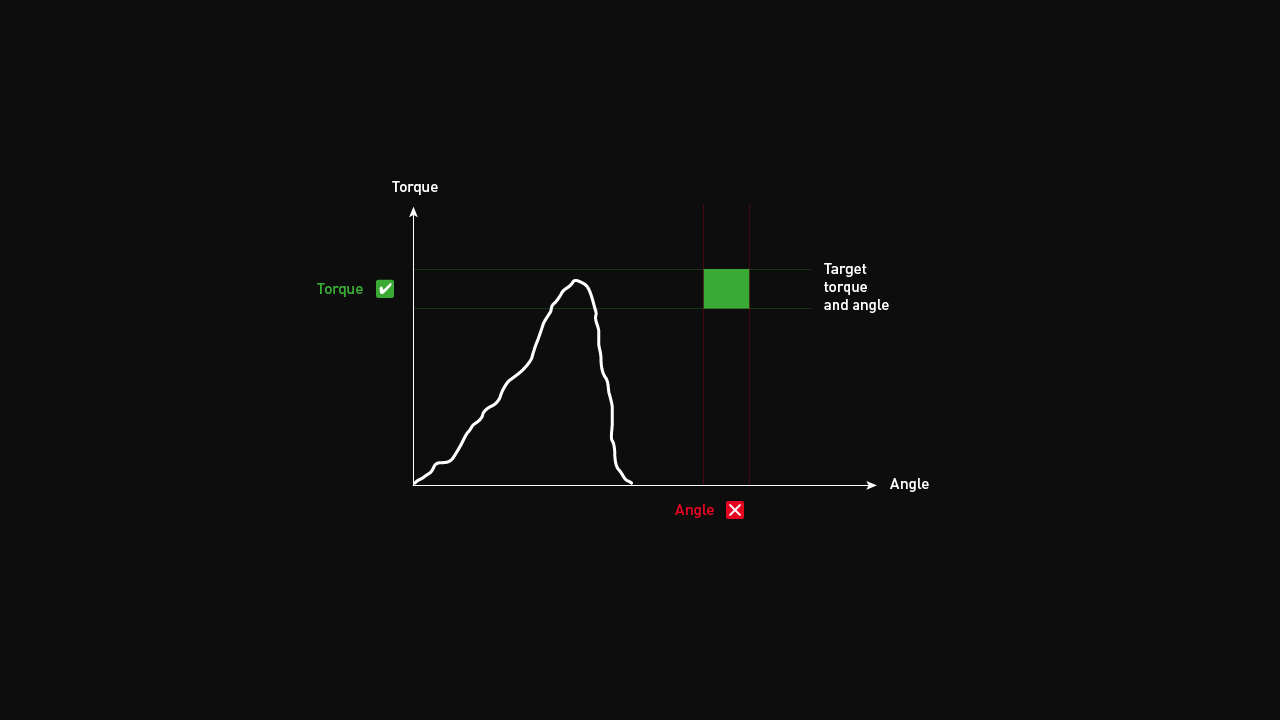

Angle value : NOK

In the case of critical joint, both values – torque and angle – must be within the specified “window”. In this case, the joint as a whole cannot be rated as OK as angle value is incorrect.

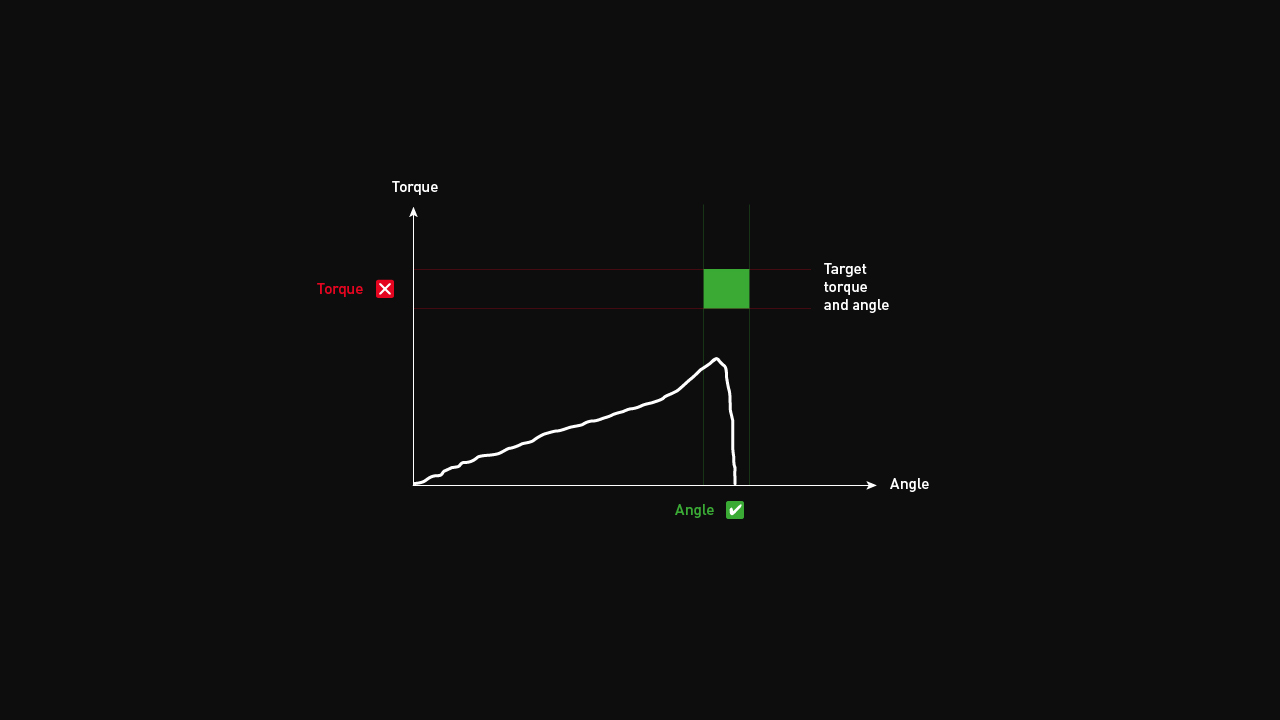

Torque value: NOK

In this new configuration, the critical joint as a whole still cannot be rated as OK as the torque value is incorrect.

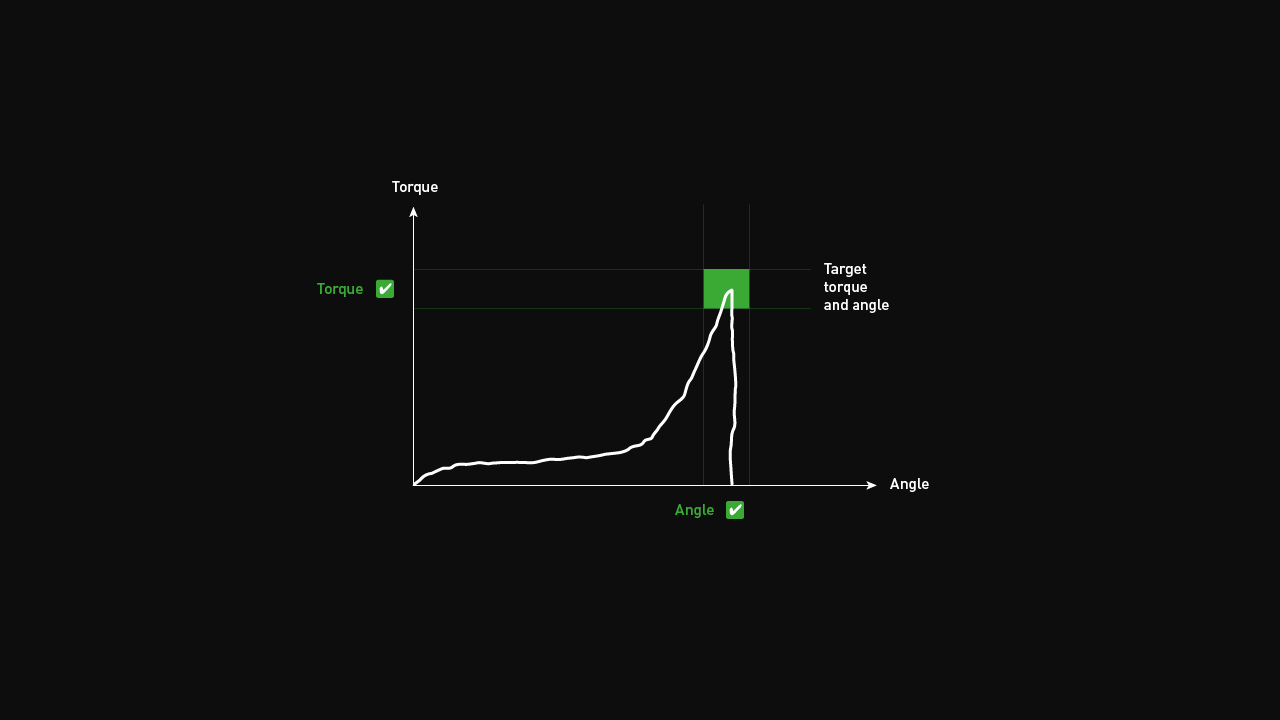

Torque and angle : OK

The critical joint can only be considered correct if both variables – torque and angle - are OK at the same time. This is the case here.

Ready for Precision Tightening - Talk with an expert!