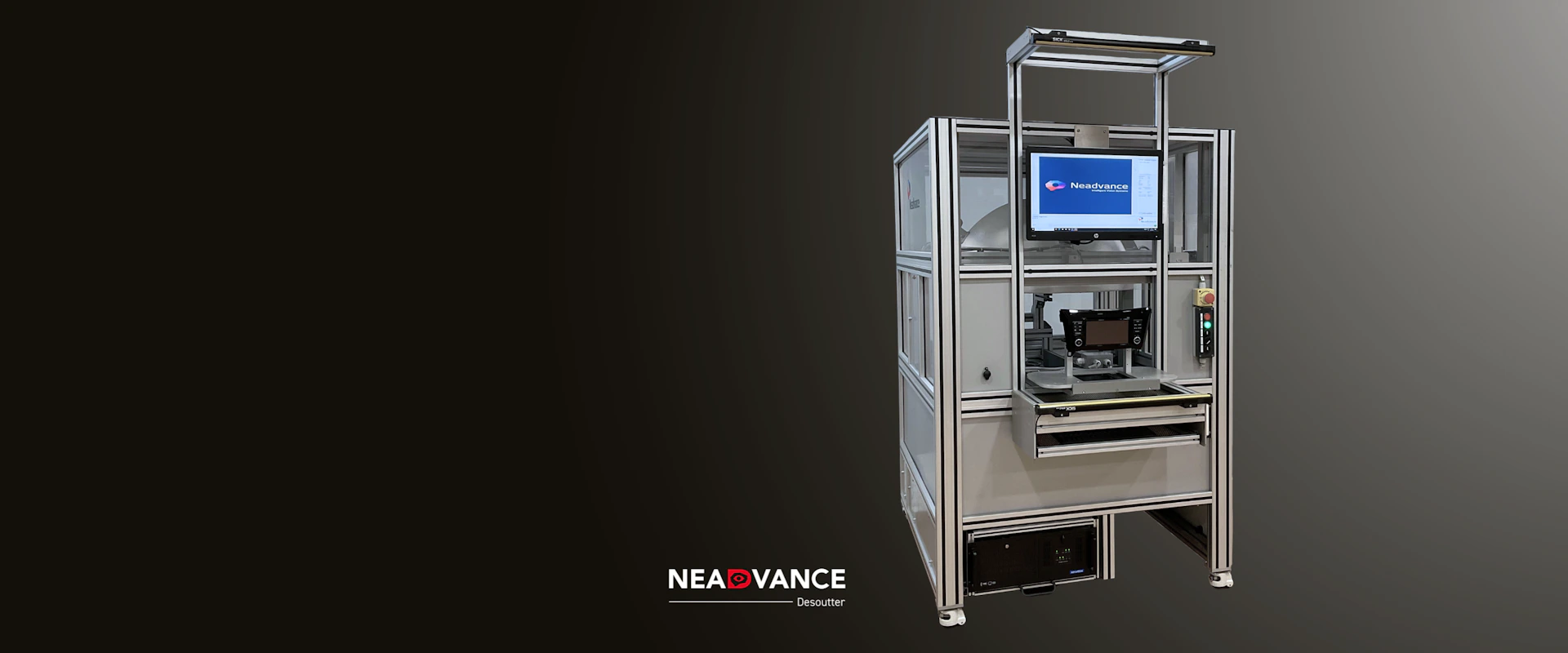

NAVIS is an automatic quality inspection system. The inspection area is equipped with strategically positioned cameras to capture comprehensive visual data. These cameras are placed around the object to ensure full coverage from multiple sides.

The inspected device is placed inside a structure that is fully covered with HIGH-POWER white LEDs to create a uniform, diffuse illumination environment. The device is automatically inspected and the system stores and sends the inspection results to the Factory Information System (FIS).

Made for automotive infotainment & electronic equipment’s

We answer your quality control challenges

In a context of increased complexity in mechanical and electronic components for automotive infotainment systems, it is crucial to ensure that all devices reach the client in perfect condition and functioning according to specifications.

This standard and ready to use inspection quality system, NAVIS, ensures flawless delivery by combining hardware integration, AI, and traceability to handle high-complexity inspection tasks.

Its typical applications include infotainment equipment, electronic control units (ECUs), Vehicle Control Units (VCU), safety and cockpit systems, meters and domain controllers, and car navigation systems.

Inspect smarter. Produce better.

Repetitive Tasks

Automatic inspection

Critical Quality Requirements

Zero-defects

High Cost of Failure

Efficient Production

Labels, barcodes and housing inspection

Antenna connectors, main connector pins

Clips, pins alignment and depth verification

Screws and springs

Front panel buttons and keys

Fuse value identification and reading

Discover NAVIS Dome, NAVIS TT and NAVIS Slim

In video

Navis's key benefits

Optimized Performance

Designed specifically for high-volume production and adaptable across various inspection tasks.

Fully integrated

Connects to multiple cameras, factory systems, and PLCs with minimal configuration.

Customer ownership

Graphical environment with intuitive drag-and-drop tools.

AI-ready

Machine learning for advanced defect detection and continuous improvement.

Scalability

Can be scaled across multiple lines with centralized training and deployment pipelines. 1 software for versatile applications and systems.

Traceability and compliance

Logs inspection data and links it to serial numbers, ensuring full traceability and audit.

Optimized Performance

Designed specifically for high-volume production and adaptable across various inspection tasks.

Fully integrated

Connects to multiple cameras, factory systems, and PLCs with minimal configuration.

Customer ownership

Graphical environment with intuitive drag-and-drop tools.

AI-ready

Machine learning for advanced defect detection and continuous improvement.

Scalability

Can be scaled across multiple lines with centralized training and deployment pipelines. 1 software for versatile applications and systems.

Traceability and compliance

Logs inspection data and links it to serial numbers, ensuring full traceability and audit.

Proven inspection system

24 million per year

Electric equipments inspected

20 years of experience

In quality control inspection

7 million per year

Inspections performed

Opening New Horizons!

Get the best-fit build topology based on your specific needs including device size, takt time and footprint

Find your Neadvance NAVIS model based on your needs to achieve the best inspection. Designed for larger devices requiring 360° inspection on all six sides.

-Big dome with high uniform light

-9 GigE cameras

-65 M Pixel system optical resolution

-Stereo 3D technology

-300x160x140 mm base inspection area

They trust us

Our customers