In today’s automated assembly environments, product designs often require multiple screw types to fasten components within a single product. Traditionally, this required multiple tightening modules, controllers, which meant higher costs, complex setups, and longer changeovers.

Desoutter’s RAPID screw feeding system now offers the Quick Change option, a breakthrough that makes multi-screw automation simpler, faster, and more cost-effective.

What is Quick Change for RAPID screw feeding systems?

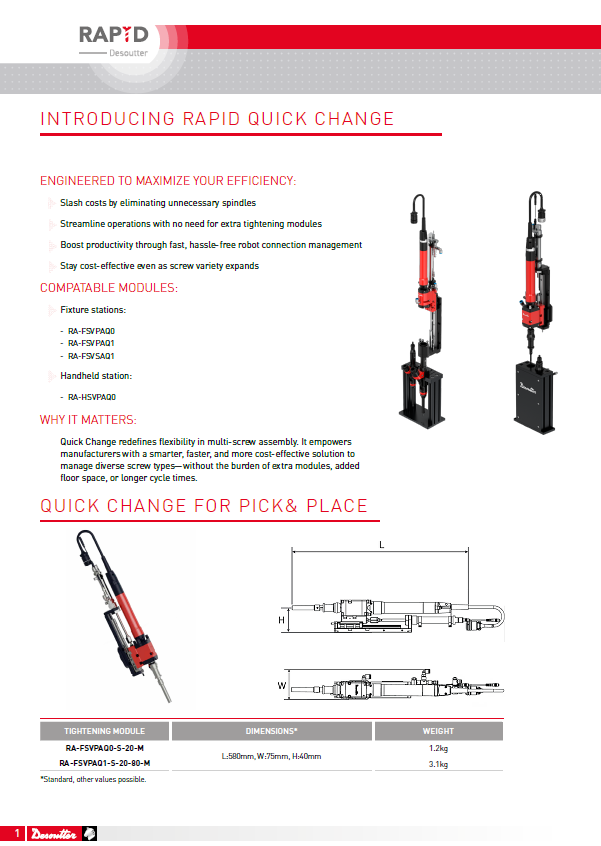

Quick Change is a new functionality available for RAPID screw feeding systems and delivering unmatched flexibility for manufacturers. Instead of installing separate tightening modules and spindles for each screw type, Quick Change lets you switch seamlessly using a single system—keeping your assembly line lean and efficient.

How it works?

The Quick Change concept is simple yet powerful: One spindle, one controller, one tightening module — compatible with multiple loading heads for different screw types.

When you change screw size, you just swap the loading head, not the entire module. This drastically simplifies setup, reduces space requirements, and keeps the cycle time unchanged compared to more expensive whole tightening module solutions.

How does Quick Change for RAPID improve automated screw feeding systems?

Here are the key benefits that can make your process smarter and faster:

- Cost Efficiency: No need for extra spindles or dedicated tightening modules

- Flexibility: Handle multiple screw types with one solution

- Easy Integration: Quick and simple robot connection management

- Minimal Additional Cost: Even when screw variety increases

- Productivity: Hose feeding option ensures zero impact on takt time

Let's take a practical example with two different screw types,

illustrating how Quick Change simplifies setup compared to conventional multi-screw systems:

► Solution without Quick Change:

|

|

|

- 2 controllers + their mountings

- 2 tightening modules

- 2 tightening modules

- 4 sensor cables

- 2 vaccum sensor cables

- 4 cylinder tubes

|

|

|

|

|

|

|

|

|

► Solution with Quick Change for RAPID:

|

|

|

- 1 Controller + its mounting

- 1 tightening module + 1 extra loading head for the second type of screw*

- 2 sensor cables

- 1 vaccum sensor cable

- 2 cylinder tubes

*Then, for each additional screw type, an extra loading head is required.

|

|

|

As you can clearly see from the example above, when handling multiple screw types on your assembly line, Quick Change for RAPID :

→ reduces the number of required cables,

→ minimizes space usage,

→ shortens commissioning time

→ ultimately lowering labor costs by more than 50%.

In short, Quick Change for RAPID delivers a much simpler, smarter integration for multiscrew assembly needs!

Which industries and processes should adopt Quick Change for multi-screw assembly automation?

Quick Change is ideal for automatic tightening processes in industries such as automotive, electronics, and general manufacturing—where multiple screw types are common, and cost control is critical.

|

It's the ideal solution for you if you:

- Already use automatic tightening stations or assembly lines

- Need to handle multiple screw types

- Are looking for a cost-effective feeding and tightening system

|

|

Quick Change helps cut costs and maintain takt time in screw feeding automation by:

- reducing investment in additional splindles and modules

- simplifying installation with up to 50% fewer cables and components

- maintaining productivity through hose feeding (no cycle time impact)

- scaling easily as screw variety grows — without skyrocketing costs