Descarregue manuais do utilizador, ficheiros CAD e muito mais.

As nossas soluções em vídeo!

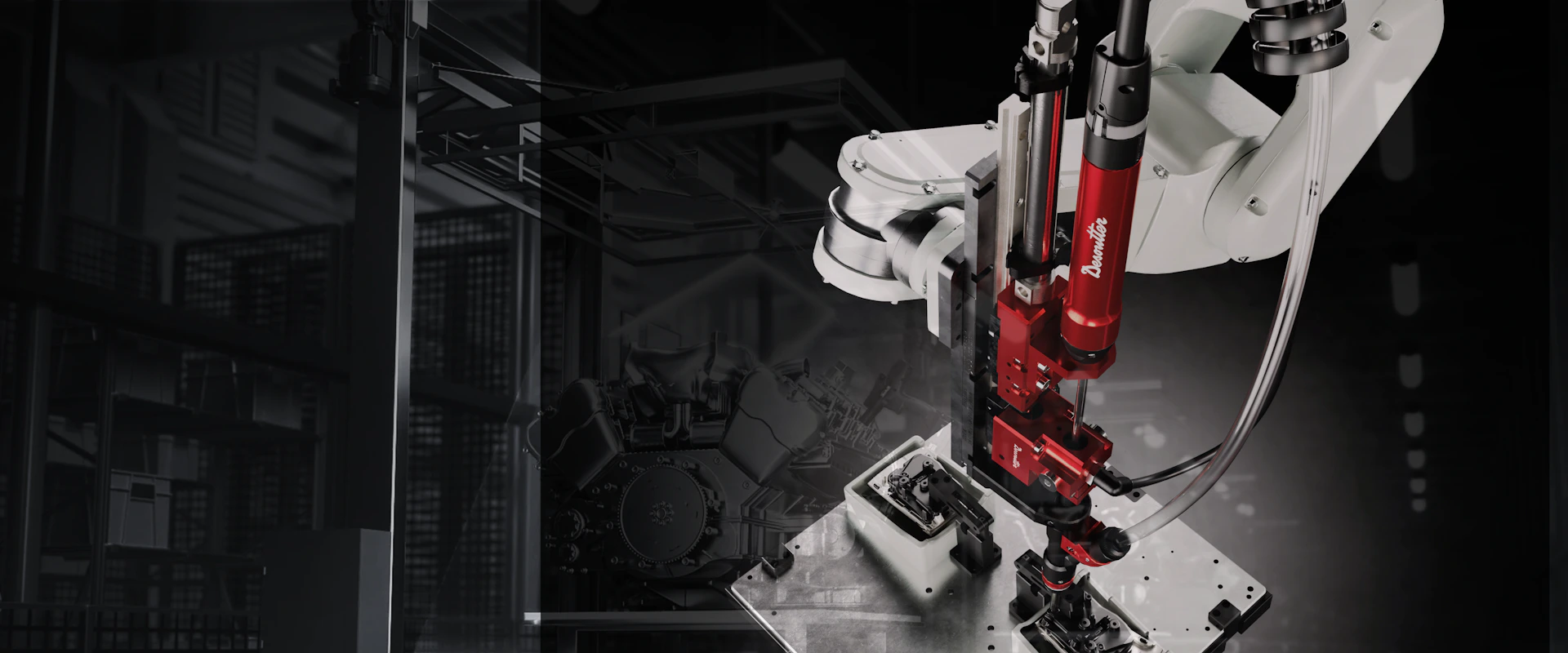

Do conceito à integração

Apoiamos os seus projetos com experiência em design e a nossa ampla gama de possibilidades de montagem

As nossas equipas de projeto centralizadas e locais estão disponíveis para trabalhar nos seus projetos. Mais do que produtividade - a Desoutter permite que os integradores criem soluções mais inteligentes, mais rápidas e preparadas para o futuro para OEMs e fornecedores Tier. Compreendemos os desafios enfrentados pelos integradores: acelerar a integração do sistema, garantir uma interoperabilidade perfeita e preparar as instalações dos seus clientes para o futuro.

Confiado por integradores de sistemas

WRT

Sistemas de medição de torque

Tudo em um para suas verificações de qualidade: um transdutor rotativo sem fio fácil de usar que se comunica por meio de uma interface de usuário web fácil de usar e captura dados de torque e ângulo, juntamente com traços, em todos os modelos para um controle de qualidade abrangente.

Pivotware

Controlo de processos

Um novo nível de controlo de processos com uma estratégia de zero defeitos. Capacite a sua equipa para atingir as metas de produção e eliminar retrabalhos, tudo isso enquanto trabalha de forma autónoma com o Pivotware. Todas as ações são rastreáveis, registadas e visíveis.

Descubra as nossas soluções de aperto em vídeo

AXON. MULTI. Hastes Fixadas.

Os nossos melhores produtos de automação em vídeo

RAPID. eRAPID. ARG.

A Desoutter, líder global em soluções de montagem e perfuração, fornece aos integradores de sistemas módulos para soluções de montagem inteligentes personalizadas. O nosso portfólio avançado de ferramentas de montagem inteligentes, software de controlo de processos, automação leve e serviços oferece tecnologias que se adaptam perfeitamente ao ambiente de produção de cada cliente. Ao estabelecer uma parceria com a Desoutter, os integradores ganham acesso a soluções industriais inovadoras e fiáveis que aceleram projetos de integração, reduzem o tempo de inatividade, melhoram a produtividade e proporcionam o máximo valor aos seus clientes:

- Tempo e velocidade de comissionamento, fiabilidade no prazo de entrega e preços, risco reduzido

- Modularidade, escalabilidade, flexibilidade

- Integração, o ECOSSISTEMA Desoutter, serviço dedicado

Explore os nossos sistemas de visão automatizados em vídeo

NAVIS. nexonar.

Eles confiam em nós

Procura assistência especializada?

Alguma dúvida? Consulte as nossas perguntas frequentes

Que vantagens a Desoutter oferece aos integradores de sistemas na conceção de soluções técnicas?

A Desoutter fornece aos integradores de sistemas um ecossistema completo de soluções avançadas de montagem e controlo de processos que são fáceis de configurar e implementar. Os nossos produtos são concebidos para oferecer flexibilidade, escalabilidade e conectividade, permitindo aos integradores de sistemas criar soluções personalizadas que satisfazem os requisitos de desempenho e qualidade dos seus clientes. Além da nossa tecnologia, oferecemos suporte técnico dedicado, orientação de projetos e serviço global para ajudar a garantir o sucesso de cada integração.

Como é que a Desoutter apoia os integradores de sistemas ao longo do ciclo de vida do projeto?

Desde a fase inicial de design até ao comissionamento no local e ao serviço pós-venda, a Desoutter acompanha os integradores de sistemas em todas as etapas do processo. Oferecemos acesso a programas de formação, ferramentas de configuração digital, documentação detalhada e suporte técnico ágil. Os nossos especialistas trabalham em estreita colaboração com os integradores de sistemas para reduzir os prazos dos projetos, garantir uma implementação perfeita e proporcionar um desempenho duradouro aos utilizadores finais.

As soluções da Desoutter são compatíveis com os sistemas e equipamentos de produção existentes?

Com certeza. As soluções da Desoutter são baseadas em padrões de comunicação abertos e são projetadas para fácil integração em uma ampla variedade de ambientes industriais. Seja para conexão com sistemas MES, ERP ou de rastreabilidade, nossos produtos garantem interoperabilidade e escalabilidade. Isso significa que os integradores de sistemas podem modernizar com confiança as linhas de produção de seus clientes sem interromper as operações existentes.

Como é que a Desoutter garante a integridade e a rastreabilidade dos dados em sistemas integrados?

As soluções da Desoutter são projetadas para garantir total integridade dos dados e rastreabilidade de ponta a ponta em todos os sistemas conectados. Os nossos controladores e plataformas de software coletam, armazenam e trocam dados de processo em tempo real com segurança, suportando protocolos industriais importantes, como OPC UA, MQTT e REST API. Isto permite que os integradores de sistemas criem arquiteturas confiáveis e orientadas por dados que estão em conformidade com a Indústria 4.0 e os padrões de garantia de qualidade, ao mesmo tempo que fornecem visibilidade completa de cada etapa de aperto ou processo.

Que tipo de informação é enviada por um sistema de visão para uma estação ou orquestrador de linha para operações de aperto ou furadeira?

Um sistema de visão fornece as coordenadas precisas dos pontos de aperto ou furadeira dentro da estrutura de referência do robô. Na Desoutter, essas coordenadas são fornecidas em três dimensões, garantindo máxima precisão e repetibilidade para processos automatizados. Isso é fundamental para integradores que trabalham em linhas de montagem complexas em setores como o automotivo, aeroespacial e infraestruturas de alta tecnologia, como centros de dados.

Todos os principais fieldbuses podem ser usados para comunicar com um sistema de visão?

Sim. O sistema de visão Desoutter suporta todos os principais fieldbuses industriais, tornando-o altamente adaptável à maioria das arquiteturas de automação. Para os integradores, isso significa integração perfeita em ambientes multitecnológicos, sem comprometer o desempenho ou a segurança dos dados.

O que deve ser considerado ao implementar o hardware para um sistema de visão?

A posição da câmara é um fator crítico para a fiabilidade do sistema. Na Desoutter, montamos o módulo da câmara diretamente na ferramenta de aperto ou perfuração, proporcionando máxima flexibilidade e ganhos de produtividade. Esta abordagem reduz as restrições de espaço e simplifica a implantação em linhas de montagem complexas, onde a precisão e a eficiência são fundamentais.

Que tipos de sistemas robóticos podem funcionar com um alimentador de parafusos?

O alimentador de parafusos RAPID da gama Desoutter foi concebido para oferecer uma ampla compatibilidade e pode ser integrado perfeitamente em várias plataformas robóticas, tais como robôs industriais, robôs colaborativos (cobots), modelos SCARA e até mesmo sistemas de movimento linear, como dispositivos de eixo XY.