In today’s rapidly evolving manufacturing landscape, industrial assembly tools — including advanced tightening solutions and robust drilling solutions — are more critical than ever for companies aiming to scale up efficiency, precision, and quality. The needs for automation, smart manufacturing and ergonomic, high-performance tools are rising across automotive, aerospace and general industries. In assembly line manufacturing, equip your production line to meet modern manufacturing demands: faster cycles, consistent quality, improved worker safety, and seamless integration into automated workflows.

Industrial assembly solutions

Let's talk

We’re here to support you at every stage of your development process.

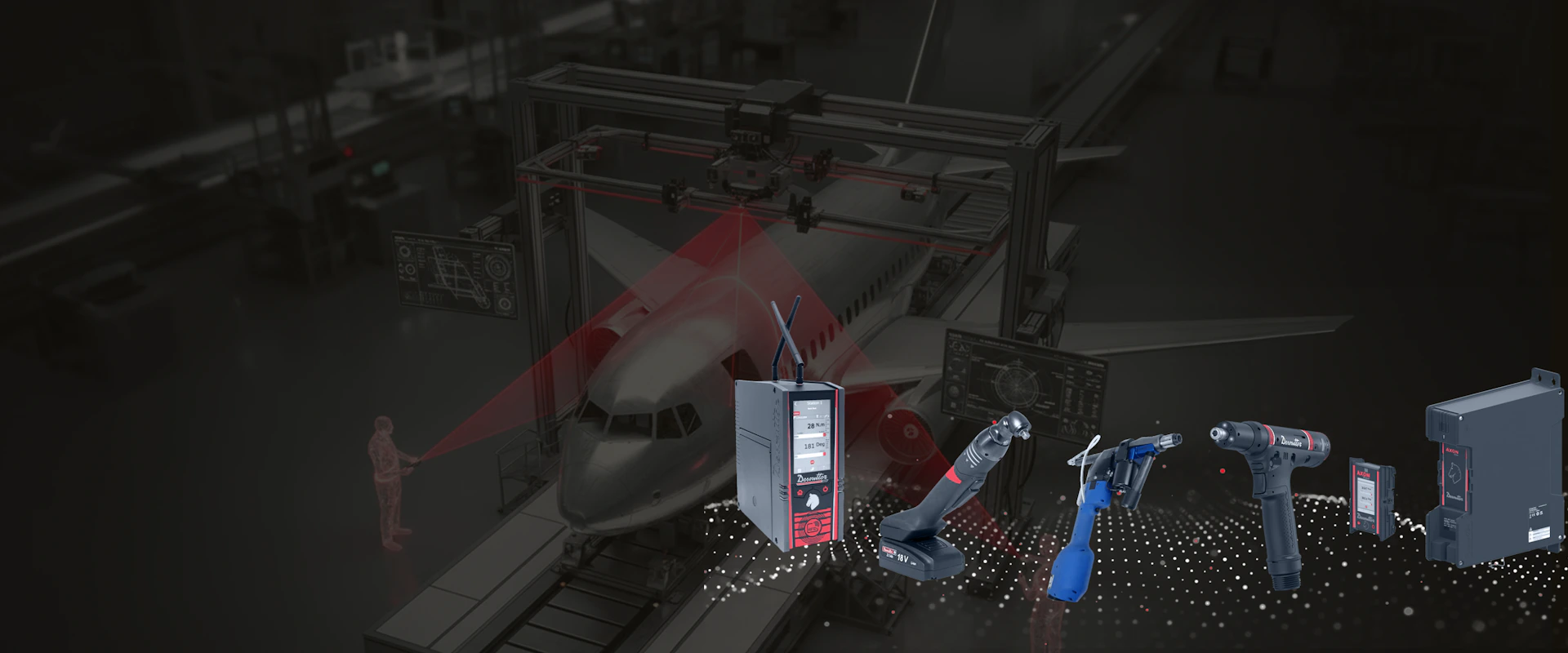

Desoutter's industrial tools engineered for precision, safety and full traceability

Having the right industrial tools ensures that every joint, every bolt and every hole meets the highest standards of quality and safety. For that, our robust assembly tools are certified to strict industry standards in tightening, drilling and automation. In addition, Desoutter tools ensure reliable assembly as they deliver real-time DATA feedback empowering you to act instantly or analyze data afterward for smarter, faster production control:

- -Detect and correct assembly errors instantly

- -Traceability ensuring compliance and fast root cause analysis

- -Line optimisation by analyzing data performance collected

One partner for all applications of your production line.

All tools are customizable on demand to fit with unique requirements.

Optimize process integration through a unified setup approach.

Certified to strict industry standards in tightening, drilling and automation.

Comprehensive internal validation Protocol.

Trusted by most demanding manufacturers.

Frequently asked questions about industrial assembly tools

What are industrial assembly tools and why are they essential in manufacturing?

Industrial assembly tools are specialized fastening solutions used to tighten, secure, or assemble components in manufacturing environments. They ensure consistent torque control, high productivity, and reliable quality assurance across assembly lines. Modern intelligent tools also provide real-time data and process traceability, helping manufacturers reduce errors and optimize performance.

How do intelligent or connected assembly tools improve production quality?

Connected industrial assembly tools use sensors and software to monitor torque, angle, and fastening parameters in real time. This enables automatic error detection, documentation of every tightening cycle, and improved traceability. As a result, manufacturers gain higher process reliability, reduced rework, and better compliance with industry standards.

What factors should I consider when choosing the right industrial assembly tool for my application?

Key criteria include the required torque range, fastening precision, ergonomics, tool durability, and compatibility with your existing assembly systems. For advanced applications, features such as wireless connectivity, smart controllers, and data integration with quality management systems can significantly enhance production efficiency and traceability.