Inspect smarter. Produce better.

This standard and ready to use system ensures flawless delivery by combining hardware integration, AI, and traceability to handle high-complexity inspection tasks.

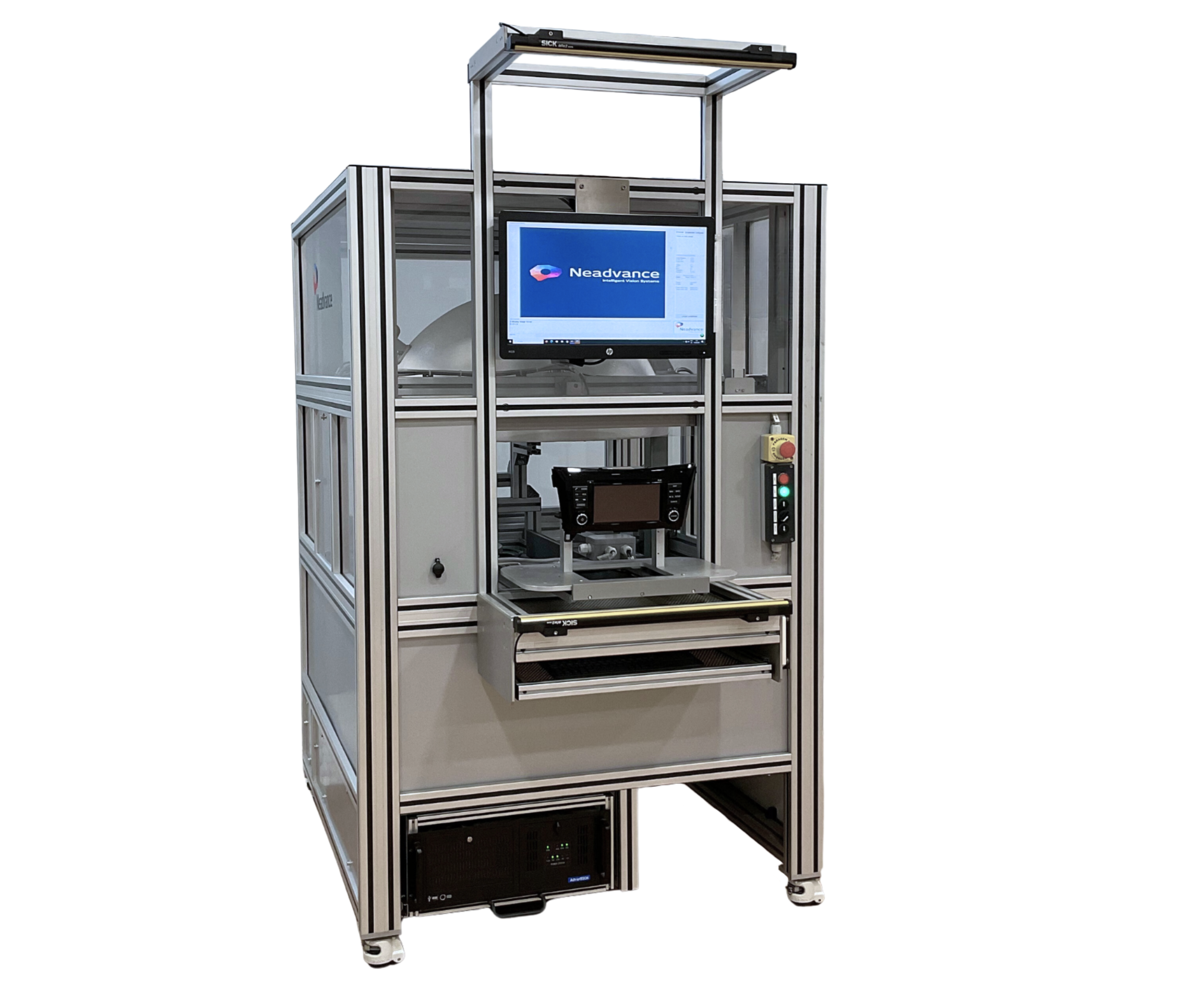

NAVIS: the automatic quality inspection answering the manufacturing needs

NAVIS, from Neadvance product range, is an automatic quality inspection system. The inspection area is equipped with strategically positioned cameras to capture comprehensive visual data. These cameras are placed around the object to ensure full coverage from multiple sides.

NAVIS was born of some observation:

- High-volume, repetitive tasks need automatic inspection in order to faster line throughput and get less expenses on labor

- Critical quality requirements need automated, precise vision inspection to ensure zero-defect delivery and less PPM levels

- Disconnected systems need seamless traceability and data integration in order to have traceability and quality control assurance and effective and efficient FMEA

- High cost of failure must be replaced by an efficient production to reduce the total cost of quality and erase human errors