nexonar NEO is the latest addition to the nexonar product family, developed to meet the increasing demand for precision and control in assembly operations. Designed as a scalable Real-Time Location System (RTLS), NEO helps manufacturers ensure that critical tightening tasks are completed in the right place, at the right time – every time. Whether it comes to assembling battery packs, seats, engines, or operating at the workbench, NEO delivers unmatched positioning accuracy and quality improvements where it matters most.

In today’s high-stakes production environments, a Real-Time Location System not optional. Missing fasteners, Re-hit, wrong sequence, and not well managed NOK tightening’s can lead to serious quality issues such as leakage, part damage or costly rework. NEO addresses these challenges by delivering real-time, high-resolution positioning data to track and validate tightening tool movements during the assembly process.

Why NEO?

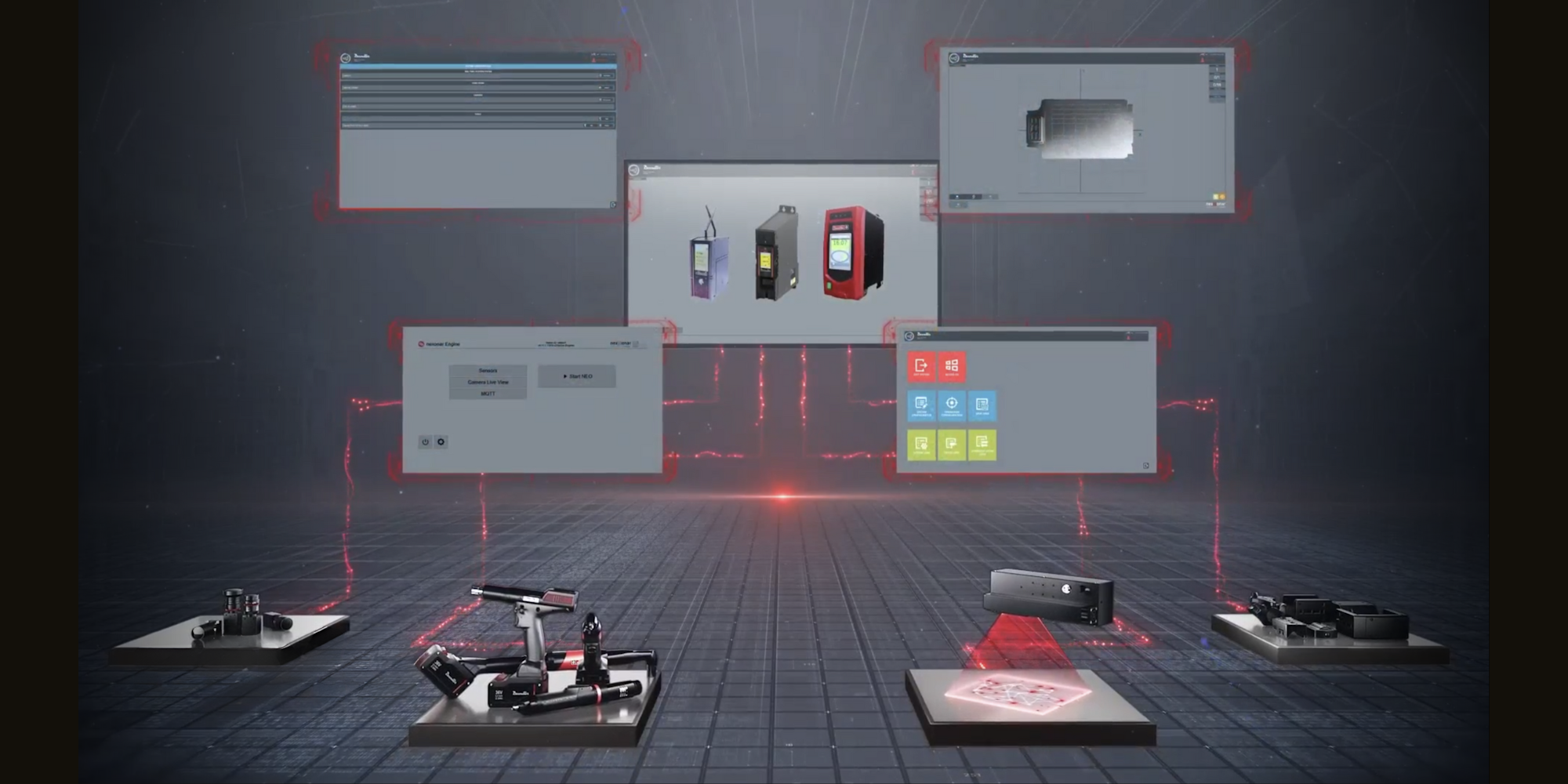

NEO was developed with a clear focus: simplify integration with Desoutter products, increased flexibility, and reduced configuration workload. NEO integrates seamlessly with the Desoutter ecosystem, compatible with tightening tools through hubs, terminals, and controllers. It allows for intuitive configuration, Psets and assembly process information that can be loaded directly from the Connected Assets, streamlining initial setup and daily operation. The user interface is consistent with Desoutter’s existing software landscape, therefore minimizing training effort for operators and technicians.

Scalable, Stable, and Smart

NEO supports configurations ranging from simple single-camera workstations to complex setups with up to four cameras and four tools. It uses active infrared technology to provide stable, interference-free wireless tracking, and delivers data at a frame rate of up to 163 Hz — with submillimetre resolution. The flexible camera placement supports both static and dynamic workspaces, making NEO suitable for a wide range of use cases including but not limited to battery pack assembly, seat installation, engine production, and bench-top tasks.

Integrated for the Future

For manufacturers scaling up from basic RTLS applications, it provides a natural next step with added functionality and feature management, while still remaining cost-effective. As part of the Desoutter ecosystem, NEO supports advanced process control, system integration, and data-driven optimization. Collected process data can be analyzed to improve performance, and support preventive maintenance and quality assurance efforts over time.