Problemas de rede

Diferente dos equipamentos de produção, cuja manutenção pode ser planejada, uma rede sem fio pode estar funcionando em um minuto e falhar no seguinte — sem aviso prévio e sem indicação de como resolver. Às vezes, uma falha na rede se agrava porque não está claro quem deve assumir a responsabilidade de restaurá-la. É função do gerente de operações ou do gerente de TI responder a esses problemas?

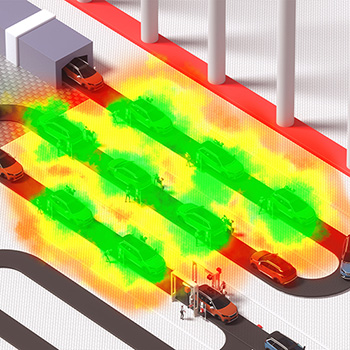

A comunicação sem fio é uma tecnologia relativamente nova, por isso os gerentes de operações e as equipes de qualidade — embora altamente experientes em métodos mecânicos de produção — nem sempre possuem as competências necessárias para projetar e implementar uma rede de produção baseada em wireless. Como resultado, a responsabilidade geralmente recai sobre a equipe de TI, que pode entender os princípios básicos da comunicação sem fio, mas normalmente carece do conhecimento específico necessário para aplicá-la com sucesso em um contexto industrial. O mesmo ocorre com fornecedores externos de Wi-Fi: eles sabem como avaliar uma rede, realizar uma pesquisa de Wi-Fi e construir um mapa de calor, mas faltam-lhes a expertise industrial vital.

Isto pode levar a problemas reais. Se a tecnologia sem fio escolhida não for adequada ao propósito, será inerentemente pouco confiável. Assim, em vez de melhorar a produção, migrar para o wireless pode gerar mais problemas do que aqueles que deveria resolver. Problemas técnicos podem causar atrasos — o que aumenta os custos.